Recyclables are collected from your house in two ways. There are kerbside "sort" programs where recyclables are classified into their various materials by the householders and normally collected on separate or multi-chamber vehicles; and co-mingled collections, in which your whole recycling is put into a single compartment before being taken to a Materials Recovery Facility (MRF).

All the mixed recycling is then categorised by hand or machine (or both) at the MRF before being sent to manufacturers who turn it into new goods. Recycled materials become valuable commodities in the global market once they've been collected and sorted.

What is Recycled in the UK?

Paper and card account for the majority of what is recycled, with around 68% of all paper being turned into new paper products. Glass makes up most of the remainder, with around 76% being recycled into new bottles and jars. Metal is recycled at a rate of over 59%, while plastic has the lowest recycling rate at just 16%.

So, it's important that we recycle as much as possible to keep this industry thriving. It's also great for the environment – every tonne of recycled plastic saves 5,774 kWh of energy, 16.3 barrels of oil, and 30 cubic yards of landfill space!

If you're a business owner and keen to do your bit, then make sure to get in touch with us today here at Materials Recovery so that we can facilitate your whole recycling process so that you can become more sustainable and environmentally friendly.

Does the UK Export Recyclable Materials?

Because they do not have readily accessible sources of virgin materials (no indigenous forests or oil supplies) and have a large manufacturing sector that demands them, countries such as China and European Countries are prepared to pay high prices for recyclables like waste plastic.

It's better for the environment to export our recyclables than to use virgin, raw materials even though exporting our waste means a greater recycling loop since recyclable items will be carried further.

Recyclable Materials

Now, let's have a look at where each type of recyclable materials goes and what happens to them once they've been collected:

Paper

When paper arrives at the mill, it is loaded into a de-inker, which uses a chemical washing technique to remove ink from paper fibres. After de-inking, the paper is blended with water and solvents in a big blender called a "pulper." The pulp slurry is the end result of this process.

The pulp slurry is then transported to a huge washing machine that spins it at high speeds, removing any undesirable particles. The clean pulp then goes on to a press, where it is wound into rolls.

Paper, unlike other recyclables, degrades each time it is recycled, making it impossible to continually use to generate new paper. However, it can still be used as insulation for houses and to make toilet paper!

Metal

Metals are sent to a metal mill after leaving the MRF. The recycled materials are then transformed into a liquid at temperatures of up to 1538° C. Metal bars called "ingots" are formed from the molten metal, which is then cast into moulds before being transported to manufacturers who use it in everything from aluminium cans to file cabinets, tin foil, and even bridges.

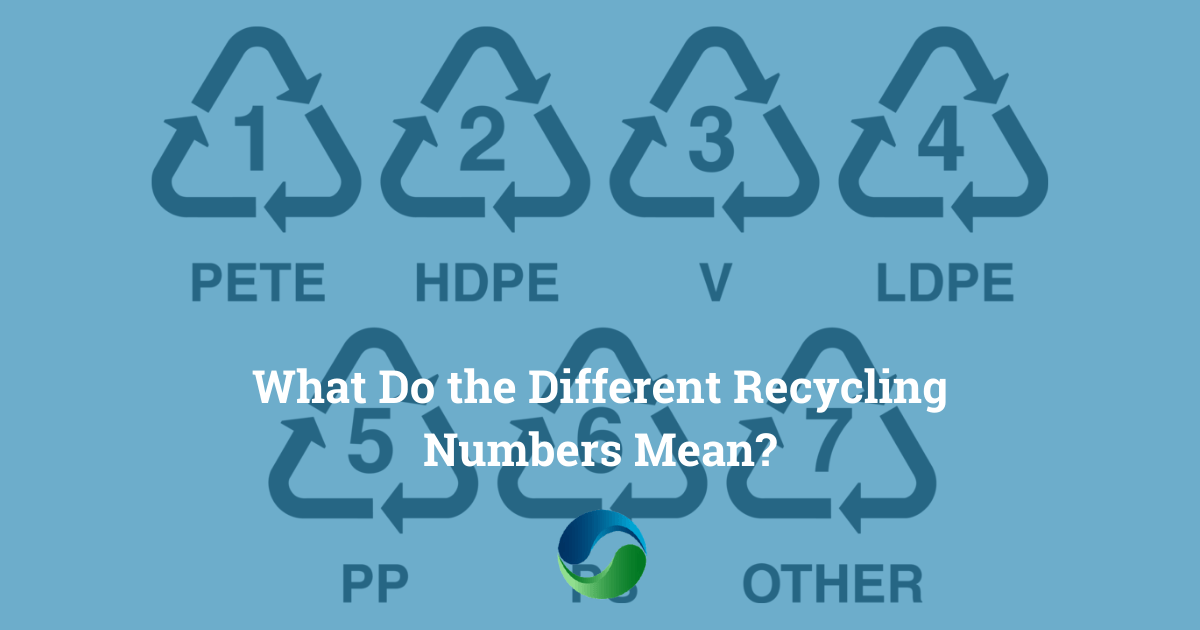

Plastic

On the underside of most recyclable plastic products, you’ll find a number. Each kind of plastic is assigned a number from one to seven, with every number representing what kind of plastic the bottle is made from. For more information on what the different recycling numbers mean - check out our blog on this very subject here.

When recyclable plastic comes into a reclaiming facility, it must be classified according to its number. The most frequent type of plastic is #1 (polyethylene), which is used in the production of products like water bottles.

Plastic is crushed, then sorted, and sent down a conveyor belt before being fed into a grinder. It's similar to plastic flakes in that it's broken down into tiny pieces. The flakes/regrind are introduced to a heat extrusion and transformed into a compound polymer. The resulting polymer can be used to manufacture new items including garden chairs, rubbish bins, and carpets.

Glass

Recycled glass may be in a variety of sizes and forms when it arrives at the reclaiming facility. The first step is to reduce all of the glass to "cullet" or tiny pieces.

Before being processed, Cullet is either sent directly to glass manufacturers or put into a furnace where it's melted down and reused. Glass doorknobs, floor tiles, garden ornaments, and jewellery beads are all examples of items created from recycled glass.

There are many ways to recycle different types of materials. It's important that we all do our part to help preserve our environment. By recycling, we can keep valuable resources from being wasted and ultimately save energy and money. Let's all work together to make a difference!